Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Nel mondo dell'elettrotecnica, i fusibili sono gli eroi non celebrati. Questi piccoli dispositivi sacrificali sono la prima linea di difesa e proteggono silenziosamente apparecchiature costose, sistemi complessi e, soprattutto, vite umane dai pericoli delle sovracorrenti. Anche se possono sembrare semplici, la scelta del fusibile giusto è una decisione ingegneristica critica che è diventata più complessa che mai.

Il panorama elettrico è in rapida evoluzione. L'aumento dell'energia solare, dei veicoli elettrici (EV) e dei sistemi di accumulo di energia (ESS) significa che gli ingegneri lavorano con tensioni CC più elevate e profili di carico più complessi. In questo ambiente ad alto rischio, un fusibile scelto male non è solo un inconveniente, ma un guasto catastrofico in attesa di verificarsi. Un semplice errore di selezione dei fusibili possono portare alla distruzione delle apparecchiature, a rischi di incendio e a significativi tempi di inattività.

Questa guida completa vi guiderà attraverso i principi essenziali di dimensionamento dei fusibili. Demistificheremo valori di tensione, valori nominali attuali, e il fondamentale ma spesso trascurato capacità di rottura. Alla fine, avrete le conoscenze necessarie per selezionare il fusibile corretto per qualsiasi applicazione, assicurando che i vostri sistemi siano sicuri, affidabili e conformi.

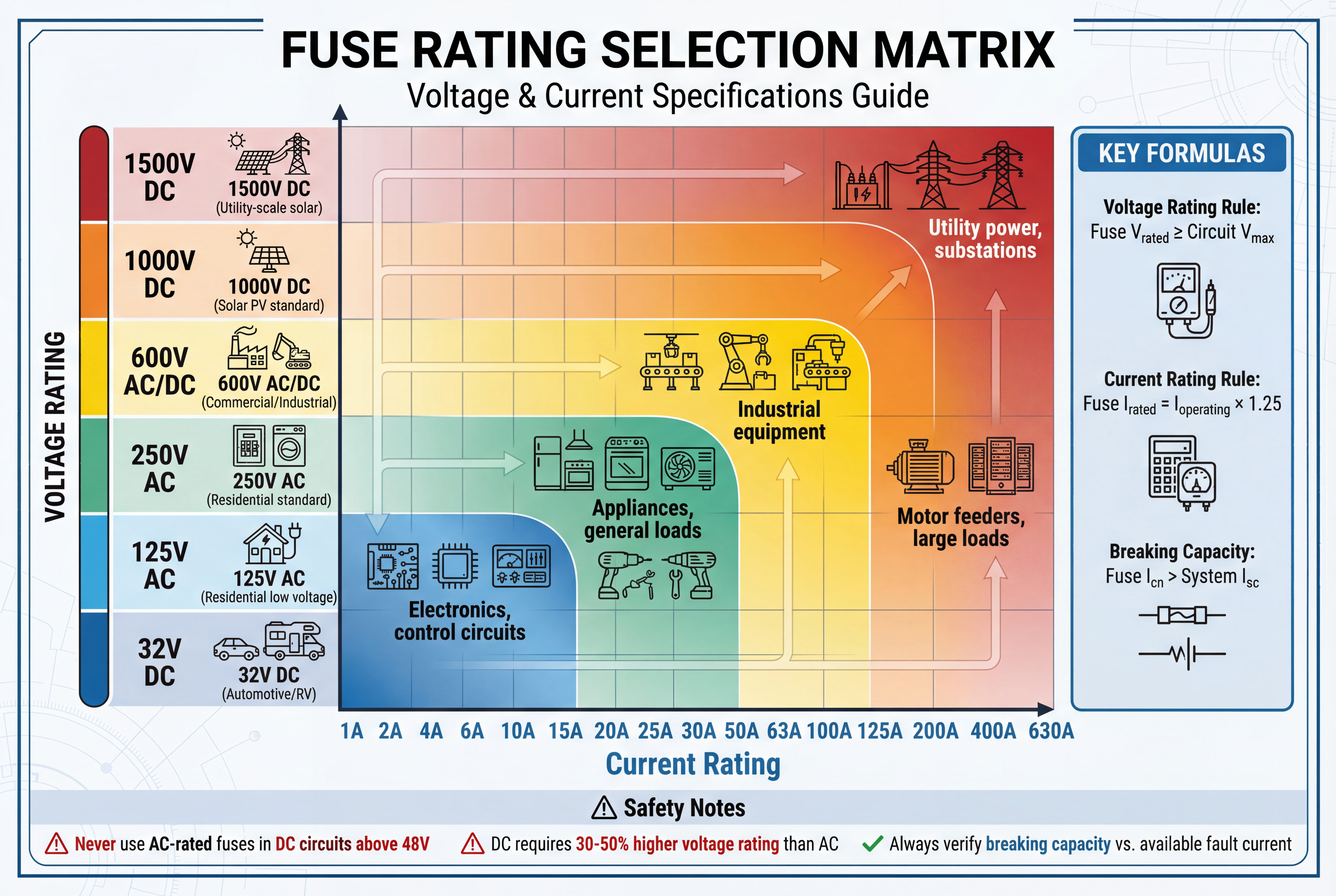

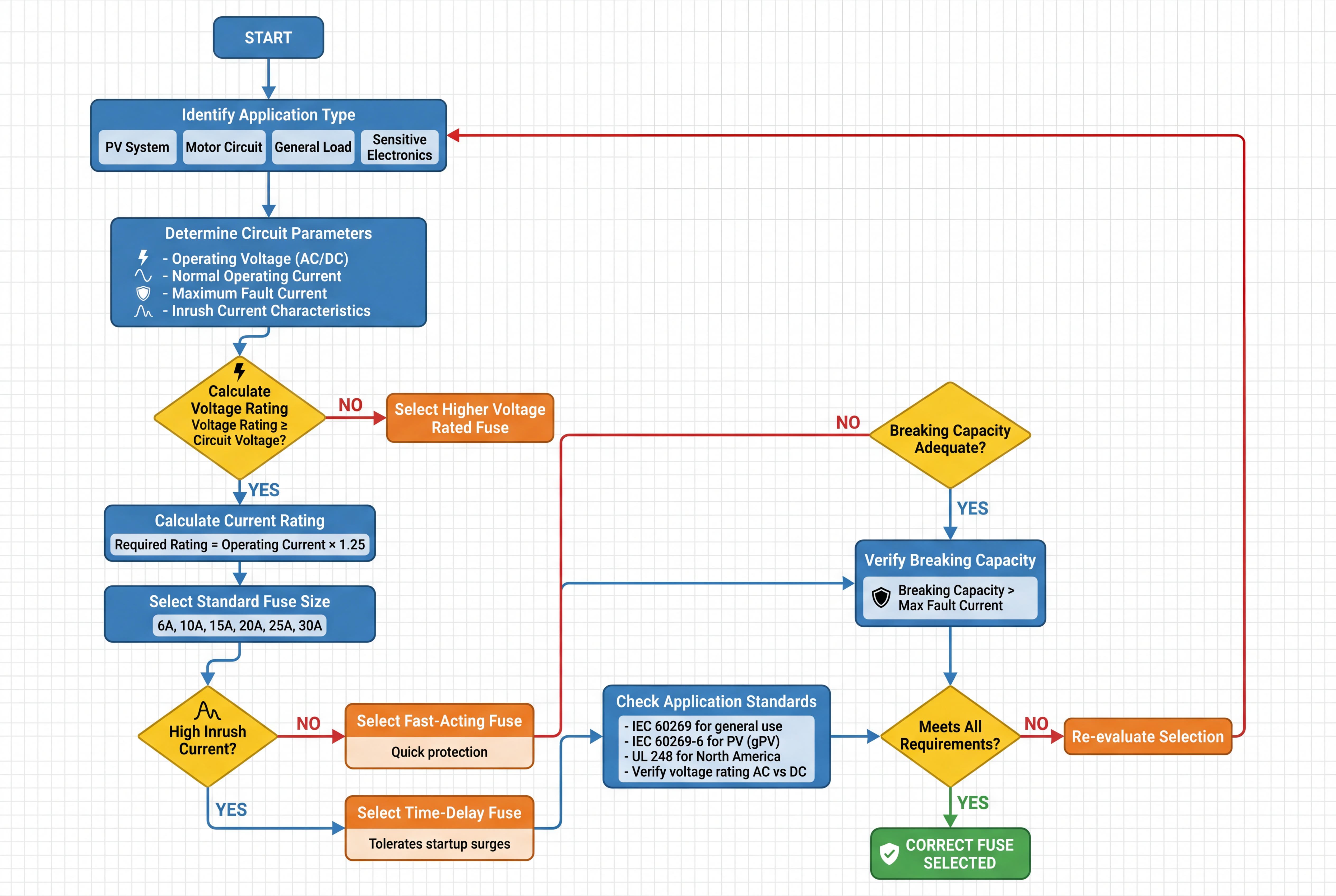

Il tensione nominale di un fusibile è forse la specifica più fraintesa, eppure è fondamentale per la sicurezza. Non indica la tensione a cui opera il fusibile, ma piuttosto il valore di tensione massima del circuito alla quale il fusibile può aprirsi in sicurezza (interrompere la corrente) durante una condizione di guasto.

La regola fondamentale della selezione dei fusibili è semplice: La tensione nominale del fusibile deve essere uguale o superiore alla tensione massima del circuito.

Quando un fusibile si brucia, l'elemento interno si fonde e crea un vuoto. La tensione del circuito cercherà di “saltare” questo spazio, creando un arco elettrico. Il fusibile è progettato per spegnere questo arco in modo sicuro. Se la tensione del circuito è superiore al valore nominale del fusibile, quest'ultimo potrebbe non riuscire a spegnere l'arco, causando un flusso di corrente prolungato, la rottura violenta del corpo del fusibile e un potenziale incendio.

L'interruzione di un circuito CA è relativamente semplice. La tensione alternata attraversa naturalmente lo zero 100 o 120 volte al secondo (a 50/60 Hz), contribuendo a spegnere naturalmente l'arco all'interno del fusibile.

La tensione continua, invece, è costante. Non esiste un punto di attraversamento dello zero. Questo rende l'arco molto più difficile da spegnere. L'energia è inarrestabile, sostiene l'arco e genera un calore intenso.

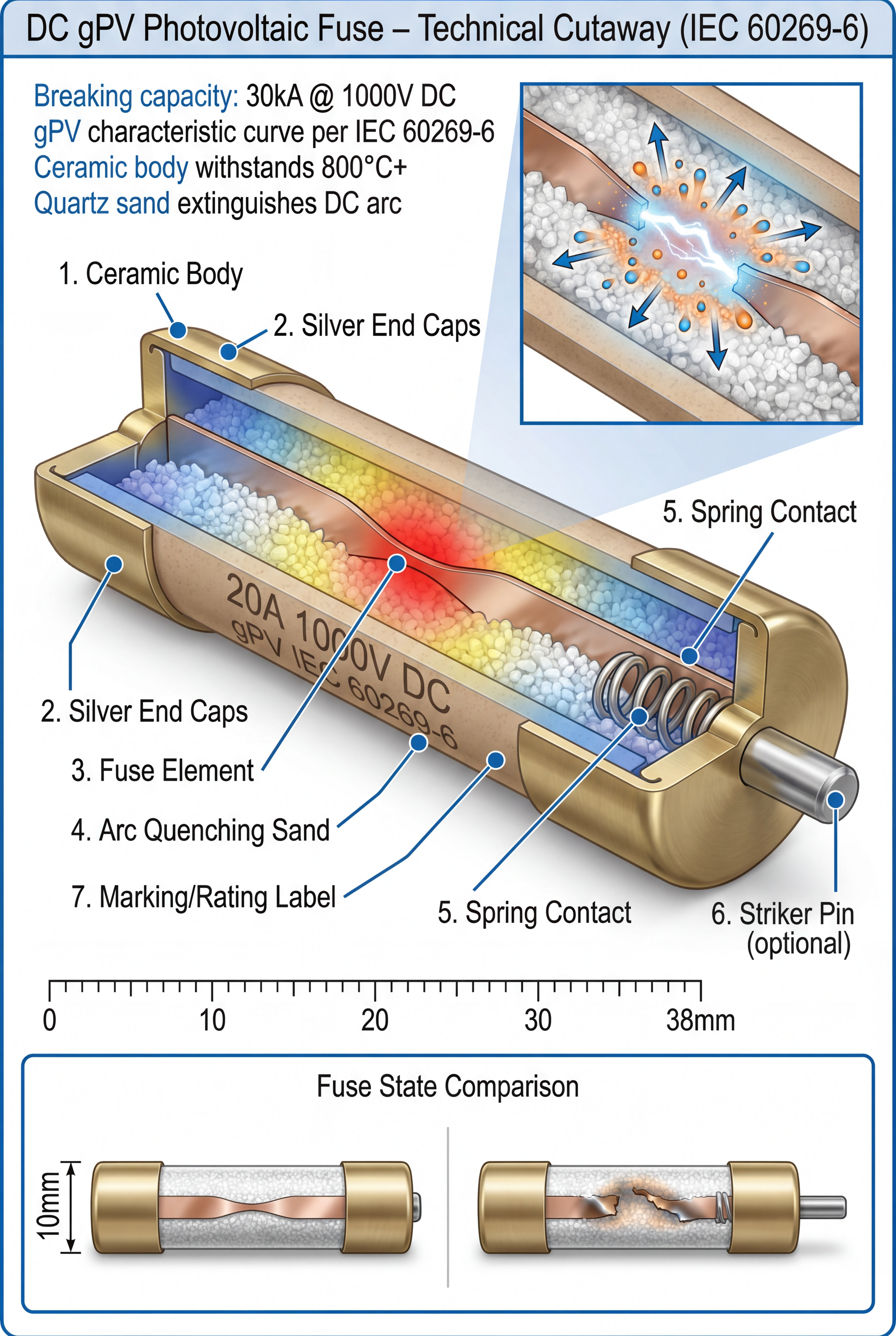

⚠️ Avvertenza di sicurezza: Non utilizzare mai un fusibile per la sola corrente alternata in un circuito in corrente continua. Un fusibile per corrente alternata probabilmente non riuscirà a eliminare in modo sicuro un guasto in corrente continua. I fusibili progettati per applicazioni in c.c. (come gPFusibili V) hanno una struttura interna speciale, spesso comprendente materiali che si spengono per l'arco, come la sabbia di quarzo, per gestire la sfida unica di interrompere le correnti CC. Utilizzare sempre un fusibile specifico per la tensione CC del sistema.

Il valutazione attuale (o potenza nominale) è la specifica con cui la maggior parte delle persone ha familiarità. Definisce la quantità massima di corrente che il fusibile può sopportare in modo continuo senza aprirsi.

Questo non significa che un fusibile da 10A si brucerà istantaneamente a 10,1A. I fusibili hanno un “tempo di fusione” specifico che è inversamente proporzionale alla corrente. Un piccolo sovraccarico lo farà aprire dopo un periodo più lungo, mentre un cortocircuito importante lo farà aprire quasi istantaneamente.

Per i carichi continui, gli standard industriali come l'articolo 240 del National Electrical Code (NEC) richiedono un margine di sicurezza. Una regola empirica comune è quella di dimensionare il fusibile ad almeno 125% della corrente di funzionamento continuo del circuito.

Formula: Valore nominale minimo del fusibile = Corrente di funzionamento normale × 1,25

Questo fattore di declassamento tiene conto delle variazioni della temperatura ambiente e delle normali fluttuazioni di carico, evitando interventi fastidiosi e garantendo al contempo una robusta protezione elettrica. Ad esempio, un circuito con un carico continuo di 8A dovrebbe essere protetto da un fusibile di almeno 10A (8A × 1,25 = 10A).

| Corrente di circuito (continua) | Fusibile minimo (calcolato) | Dimensioni standard consigliate | Margine di sicurezza |

|---|---|---|---|

| 8 A | 10 A | 10 A | 25% |

| 12 A | 15 A | 15 A | 25% |

| 16 A | 20 A | 20 A | 25% |

| 22 A | 27.5 A | 30 A | 36% |

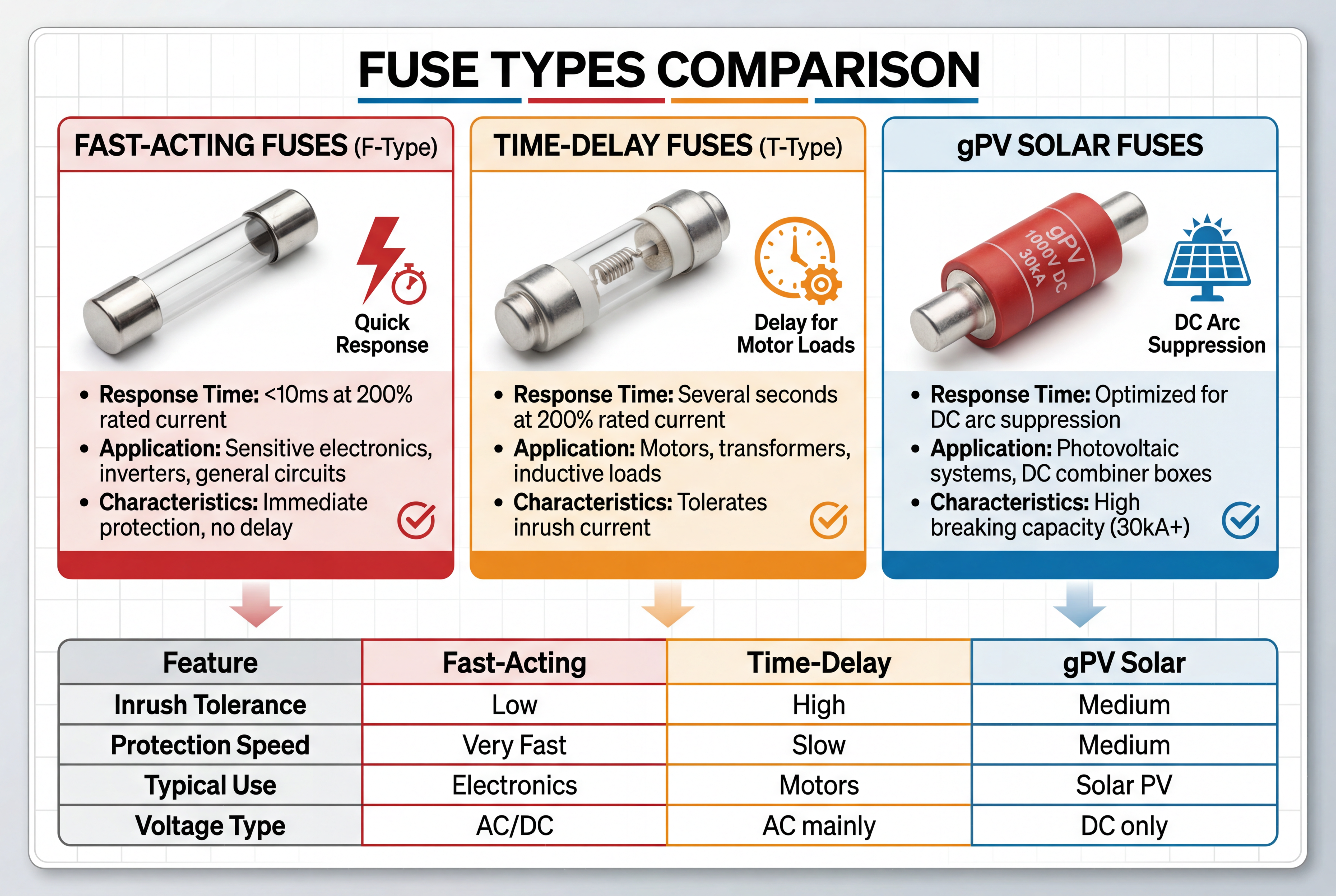

Non tutti i fusibili sono uguali. La loro struttura interna determina la rapidità con cui reagiscono a una sovracorrente, definendo la loro tipo di fusibile. Le tre categorie più comuni sono quelle dei fusibili ad azione rapida, dei fusibili a ritardo e dei fusibili specializzati, come i gPV per il solare.

| Tipo di fusibile | Tempo di risposta | Applicazioni tipiche | Tolleranza allo spunto | Tipo di tensione | Capacità di rottura |

|---|---|---|---|---|---|

| Ad azione rapida (F) | Molto veloce (<10ms con alto sovraccarico) | Elettronica sensibile, inverter, carichi resistivi | Basso | CA o CC | Varia (da basso ad alto) |

| Ritardo (T) | Lento (alcuni secondi con basso sovraccarico) | Motori, trasformatori, carichi induttivi | Alto | Principalmente in corrente alternata, in parte in corrente continua | Varia (da basso ad alto) |

| gPV (solare) | Ottimizzato per archi in corrente continua | Stringhe solari fotovoltaiche, scatole combinatore, sistemi CC | Medio | Solo DC | Molto alto (10kA - 50kA) |

Mentre i valori nominali di tensione e corrente si riferiscono alla gestione del normale funzionamento, capacità di rottura (chiamato anche Valutazione dell'interruzione o Icn) consiste nel sopravvivere allo scenario peggiore. È la corrente di guasto massima che un fusibile può interrompere in modo sicuro senza rompersi o causare un pericolo.

Se si verifica un cortocircuito, la corrente può raggiungere momentaneamente migliaia di ampere. Se il potere di interruzione del fusibile è inferiore a questa corrente di guasto disponibile, può letteralmente esplodere, non riuscendo a fermare la corrente e creando un pericoloso arco elettrico.

Regola: Il potere di interruzione del fusibile deve essere superiore alla massima corrente di guasto potenziale nel punto di installazione.

L'elevato potere di interruzione dei fusibili come i modelli gPV è ottenuto grazie a una costruzione robusta. Una struttura resistente corpo in ceramica contiene l'intenso calore e la pressione, mentre lo spazio interno è riempito di materiale di elevata purezza. sabbia di quarzo. Durante un guasto, la sabbia si scioglie intorno all'arco, assorbendo l'energia termica e contribuendo a spegnerlo in modo rapido e sicuro.

Un processo strutturato assicura che tutti i fattori critici siano presi in considerazione e che la selezione dei fusibili sia sicura e affidabile.

Tensione massima del sistema = 20 × 49,5 V × 1,15 = 1138,5 V CC. Dobbiamo selezionare un 1500V DC fusibile nominale.Fusibile minimo = 9,8A × 1,25 = 12,25A.La scelta corretta è un Fusibile da 15A, 1500V DC, gPV con potere di interruzione di 30kA.

| Applicazione | Considerazioni chiave | Tensione tipica | Corrente/Protezione tipica | Standard |

|---|---|---|---|---|

| Sistemi solari fotovoltaici | Soppressione dell'arco CC, corrente inversa, bassa sensibilità alle sovracorrenti | 1000V - 1500V DC | 10A - 30A (stringhe), fusibili gPV | IEC 60269-6 |

| Stazioni di ricarica EV | Elevata corrente continua, elevato potere di interruzione, gestione termica | 400V - 1000V DC | 125A - 630A, fusibili ad alta velocità | IEC 60269-4 |

| Accumulo di energia (ESS) | Corrente bidirezionale, protezione della batteria, correnti di guasto elevate | 48V - 1500V CC | Varia ampiamente, fusibili ad alta velocità | UL 248-13 |

1. Posso utilizzare un fusibile di tensione superiore a quella richiesta dal mio circuito?\

Sì. L'utilizzo di un fusibile con una tensione nominale superiore è perfettamente sicuro. Ad esempio, è possibile utilizzare un fusibile da 600 V in un circuito da 240 V. Tuttavia, non si può mai utilizzare un fusibile di valore inferiore.

2. Cosa succede se si utilizza un fusibile CA in un circuito CC?\

⚠️ È estremamente pericoloso. Il fusibile CA non è progettato per spegnere un arco CC persistente. È probabile che si surriscaldi, che non riesca a eliminare il guasto e che si rompa, causando un incendio o un arco elettrico.

3. Perché i fusibili hanno un fattore di declassamento 125%?\

Questo margine di sicurezza, spesso richiesto dai codici elettrici come il NEC, previene gli “scatti indesiderati” dovuti a piccole e innocue fluttuazioni di corrente e tiene conto del calore ambientale che può influire sulle prestazioni di un fusibile. In questo modo si garantisce che il fusibile scatti solo in caso di vera sovracorrente.

4. Come si calcola la corrente di guasto massima nel circuito?\

Si tratta di un calcolo complesso che coinvolge l'impedenza della sorgente di alimentazione, la lunghezza dei conduttori e i dati del trasformatore. Per i sistemi critici, deve essere eseguito da un ingegnere elettrico qualificato utilizzando un software specializzato. Per i sistemi più semplici, si possono fare stime prudenti, ma è sempre meglio sovradimensionare il potere di interruzione.

5. Qual è la differenza tra potere di interruzione e corrente nominale?\

Valutazione attuale è la corrente normale che il fusibile può gestire in modo continuo. Capacità di rottura è la corrente di guasto massima che può interrompere in modo sicuro nel peggiore dei casi. Si tratta di specifiche completamente diverse.

6. Posso sostituire un fusibile a tempo con uno ad azione rapida?\

No. Se il circuito è progettato per un fusibile a tempo (come un motore), un fusibile ad azione rapida si brucia inutilmente ogni volta che l'apparecchiatura si avvia. È necessario sostituire il fusibile con uno dello stesso tipo (o con uno equivalente approvato).

7. Come si leggono le indicazioni e i valori nominali dei fusibili?\

I fusibili sono tipicamente stampigliati con le loro caratteristiche principali. Sono riportati il voltaggio (ad esempio, “600Vac” o “1000Vdc”), la corrente nominale (ad esempio, “20A”) e spesso il tipo di fusibile (ad esempio, “T” per il ritardo o “gPV” per il solare).

8. Quali sono gli standard da rispettare per l'acquisto dei fusibili?\

Cercate le certificazioni di enti riconosciuti. Per il Nord America, si tratta di UL (Underwriters Laboratories). Per l'Europa e molte altre regioni, è CEI (Commissione Elettrotecnica Internazionale). Per il solare, lo standard specifico è IEC 60269-6. Produttori affidabili come CNKUANGYA faranno sempre certificare i loro prodotti secondo questi standard.

La corretta selezione dei fusibili è un pilastro fondamentale della sicurezza elettrica. Anche se può sembrare complessa, si riduce a tre parametri critici: un adeguato tensione nominale, una dimensione corretta valutazione attuale, e un sufficiente capacità di rottura. Sbagliare uno di questi elementi compromette l'integrità dell'intero sistema di protezione.

Man mano che la tecnologia si spinge verso tensioni più elevate e una maggiore densità di potenza, il ruolo di questi piccoli ma potenti dispositivi diventerà sempre più cruciale. Il futuro potrebbe portare “fusibili intelligenti” con monitoraggio integrato, ma i principi fondamentali della fisica e della sicurezza rimarranno invariati. Comprendendo e applicando i concetti di questa guida, potrete garantire che i vostri progetti siano non solo funzionali ma anche fondamentalmente sicuri.

Qual è lo scenario di selezione dei fusibili più impegnativo che avete incontrato nei vostri progetti? Come pensa che l'aumento delle microgrid in corrente continua avrà un impatto sulla progettazione dei fusibili in futuro?