Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

Indirizzo

304 Nord Cardinale

St. Dorchester Center, MA 02124

Orario di lavoro

Da lunedì a venerdì: dalle 7.00 alle 19.00

Fine settimana: 10.00 - 17.00

WHAT IS MCCB: It’s 3 a.m. The phone rings. The main production line at your facility is dead silent, the control panels are dark, and a faint smell of burnt plastic hangs in the air. The culprit? A main distribution MCCB that failed to trip during a fault, causing a catastrophic panel failure instead of a controlled, isolated shutdown. I’ve seen this exact scenario play out more times than I can count in my 15+ years as a field engineer. A device that costs a few hundred dollars, ignored and assumed to be working, ends up causing hundreds of thousands in downtime and equipment damage.

A Molded Case Circuit Breaker (MCCB) isn’t just a switch; it’s the most critical line of defense between your expensive assets and the destructive power of electrical faults. Treating it as a “fit-and-forget” component is a gamble. But understanding what it is, how it works, and most importantly, how MCCB test procedures are performed, changes the game from gambling to assurance.

This guide is built from decades of field experience. We’ll go beyond textbook definitions to give you a practical, in-depth understanding of MCCBs. We’ll cover what they are, the subtle but critical differences between types, and provide a comprehensive, step-by-step framework for testing them. By the end of this article, you will have the knowledge to ensure your breakers are assets for protection, not liabilities waiting to fail.

At its core, a Molded Case Circuit Breaker is an electrical protection device designed to safeguard circuits from two primary dangers: overloads and short circuits . It gets its name from its housing, which is a rugged, non-conductive “molded case” typically made of glass-polyester or thermoset composite resin .

To understand its role, think of a “Protection Ladder.”

An MCCB’s primary job is to automatically open a circuit when it detects an abnormal current, preventing damage and potential fires. Unlike a simple fuse, it can be reset (manually or automatically) after the fault has been cleared, restoring power quickly.

Il risultato principale: An MCCB is an industrial-grade circuit protector. It’s distinguished from a residential MCB by its higher current ratings, significantly higher fault-interrupting capacity, and robust construction designed for demanding commercial and industrial environments.

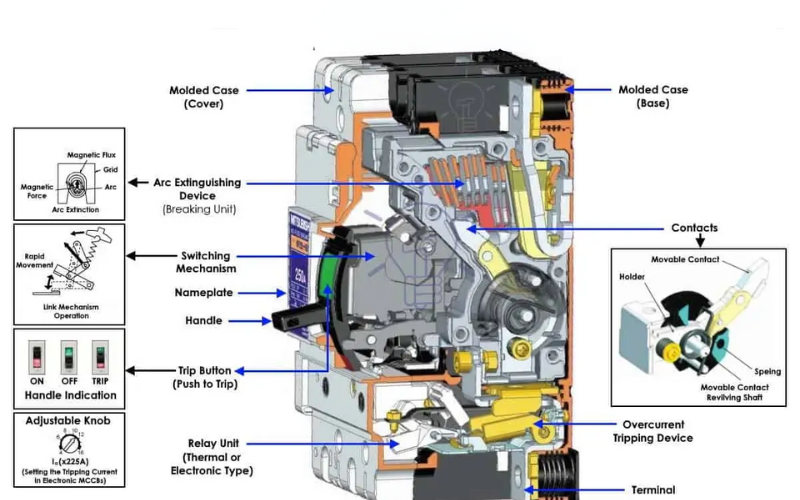

To truly appreciate an MCCB, you need to look inside the molded case. Its operation is a sophisticated interplay of mechanical and electromagnetic principles, designed to react in milliseconds. There are three core functions at play: overload protection, short circuit protection, and arc extinction.

Image showing the complex internal architecture of a standard MCCB.

The mechanical operating mechanism is responsible for rapidly separating the contacts when a trip is initiated.

Suggerimento per i professionisti: The breaking capacity (Icu or Ics) rating on an MCCB is not a suggestion. It is the absolute maximum fault current the breaker is certified to interrupt without exploding. Always ensure your breaker’s rating exceeds the calculated available fault current at its location, with a 25% safety margin for future system changes .

A common and dangerous mistake is assuming any MCCB will work on any circuit. The physics of interrupting Alternating Current (AC) and Direct Current (DC) are fundamentally different, and using the wrong breaker can have dire consequences.

In an AC system, the current naturally passes through zero 100 or 120 times per second (at 50/60Hz). This “zero-crossing” point provides a natural moment of assistance for extinguishing the electrical arc. The arc loses its energy and is easier to quench.

In a DC system, the current is constant. There is no zero-crossing. An arc, once formed, will happily sustain itself as long as there is sufficient voltage, making it dramatically harder to extinguish .This requires a completely different design approach.

Here’s a breakdown of the key differences:

| Caratteristica | AC MCCB | DC MCCB |

|---|---|---|

| Arc Extinction Method | Relies on current zero-crossing and a standard arc chute with metal plates. | Requires forced arc extinction. Uses magnetic “blow-out” coils to stretch the arc and larger, more complex multi-stage arc chutes. |

| Contact Materials | Leghe di argento-nichel o argento-grafite, ottimizzate per la conduttività e l'usura standard dell'arco. | Leghe a base di argento con tungsteno o altri metalli duri per resistere alla maggiore energia e alla durata prolungata di un arco CC. |

| Valori di tensione | In genere, la tensione nominale è fino a 690 V CA. Un interruttore tripolare con tensione nominale di 480 V CA potrebbe essere dimensionato solo per 250 V CC. | Specificato per la tensione CC, spesso fino a 1500 V CC per applicazioni come i sistemi solari fotovoltaici (PV). |

| Applicazioni tipiche | Distribuzione degli edifici, controllo dei motori industriali, sistemi di alimentazione commerciali. | Sistemi di energia solare, sistemi di accumulo di energia a batteria (BESS), trasporto ferroviario, distribuzione di energia CC nei centri dati. |

| Considerazioni sui test | Testato in base ai parametri di guasto CA (fattore di potenza). | Testato con una specifica costante di tempo (rapporto L/R, ad esempio T=4ms o 15ms) che simula l'induttanza di un circuito CC. |

Il risultato principale: Non utilizzare mai un interruttore magnetotermico in c.a. in un'applicazione in c.c., a meno che non sia esplicitamente contrassegnato dal produttore con una classificazione in c.c.. Il sistema di spegnimento dell'arco in un interruttore standard in c.a. non è progettato per gestire l'energia continua di un arco di guasto in c.c. e probabilmente non funzionerà in modo sicuro.

Un MCCB può rimanere inattivo per anni e poi essere chiamato a funzionare in pochi millisecondi. Fidarsi del suo funzionamento senza alcuna verifica è una negligenza. Un robusto programma di test assicura che rimanga un protettore affidabile. Quindi, how MCCB test procedure vengono eseguite correttamente sul campo? Seguiamo un processo strutturato in 6 fasi basato sulle migliori pratiche del settore. .

Prima di qualsiasi test elettrico, iniziate con gli occhi e le mani. Questo semplice passo può prevenire guasti catastrofici.

Questo test verifica l'integrità dell'isolamento dell'interruttore magnetotermico, assicurando che non vi siano dispersioni di corrente tra i poli o verso terra.

Questo test misura la resistenza dei contatti principali che trasportano la corrente all'interno dell'interruttore. Una resistenza elevata indica contatti bucati, corrosi o disallineati, che causano un surriscaldamento sotto carico.

Suggerimento per i professionisti: Eseguire sempre il test della resistenza di contatto prima il test di intervento per sovracorrente. Il test di intervento riscalda i componenti interni e ciò altera le letture della resistenza di contatto. Se è necessario eseguire il test dopo, lasciare raffreddare l'interruttore per almeno 20 minuti.

È il test più critico. Assicura che le funzioni di sgancio termico e magnetico funzionino secondo le specifiche. Questo test richiede un set di prova specializzato per le alte correnti.

Per gli interruttori automatici con unità di sgancio elettroniche, questo test verifica lo stato di salute dell'elettronica dell'unità di sgancio senza la necessità di iniettare corrente elevata. Molti set di prova moderni possono interfacciarsi direttamente con l'unità di sgancio dell'interruttore per simulare guasti e confermare che l'unità invia un segnale di sgancio al meccanismo. Si tratta di un modo rapido ed efficace per testare il “cervello” dell'interruttore.

This test is critical for ensuring the overall safety of the circuit, not just the breaker itself. It verifies that if a fault occurs between a live conductor and the earth (ground), the resulting current will be high enough to trip the MCCB within the required time .A high loop impedance can prevent the breaker from tripping, creating a dangerous situation where metallic components can become live without the fault being cleared.

Field testing is not arbitrary; it’s guided by robust industry standards that ensure consistency and reliability. The two most important standards for MCCBs are:

Even with a good testing program, issues can arise. Here are some common problems and how to approach them:

The Molded Case Circuit Breaker is a remarkable piece of engineering, designed to protect our most critical electrical systems from destruction. But like any safety device, it is only as reliable as its condition. Assuming it will work forever is a recipe for unplanned downtime and potential disaster.

By understanding how an MCCB works, respecting the differences between AC and DC applications, and implementing a robust, standards-based testing framework, you transform that breaker from a potential liability into a verified, reliable asset. The answer to “how MCCB test” is not just about a single procedure; it’s about a comprehensive approach to maintenance that guarantees protection when it’s needed most. Don’t wait for the 3 a.m. phone call to find out your defenses have failed.

1. How often should MCCBs be tested?

For critical applications like hospitals or data centers, NETA/NEMA standards recommend testing every 1 to 3 years. For less critical industrial applications, a 3 to 5-year interval is common. The frequency should be adjusted based on the breaker’s age, environment (e.g., dusty or corrosive), and criticality.

2. Can I use an AC MCCB for a DC solar application?

No, not unless it is explicitly dual-rated by the manufacturer with a specific DC voltage and breaking capacity. A standard AC MCCB will likely fail to extinguish a DC fault arc safely .

3. What is the difference between Icu and Ics ratings?

4. My MCCB feels warm to the touch. Is this normal?

A breaker carrying a significant portion of its rated load will feel warm due to I²R losses, which is normal. However, if it feels excessively hot, or if the heat is concentrated at the terminals, it indicates a problem like a loose connection or high contact resistance that needs immediate investigation.

5. What is a “current-limiting” MCCB?

A current-limiting MCCB uses a special high-repulsion contact design that forces the contacts apart extremely quickly (in 1/4 cycle or less) during a high-level fault. This interrupts the current before it can reach its full potential peak, significantly reducing the amount of destructive energy let-through to downstream equipment .

6. Why did my downstream breaker trip but not the main MCCB?

This is ideally what should happen. It’s called coordinamento selettivo. The system is designed so that the protective device closest to the fault opens first, minimizing the extent of the power outage. If the main breaker trips along with the downstream one, it indicates a coordination failure .

7. Can a sealed-case MCCB be repaired?

No. If a sealed-case MCCB fails any electrical test or has a faulty mechanism, it must be replaced. Opening a sealed case invalidates its safety certifications (like UL listing) and makes it unsafe to use .

8. Is a higher breaking capacity always better?

Yes, from a safety perspective, a higher breaking capacity provides a larger safety margin. However, breakers with extremely high ratings are more expensive. The correct approach is to perform a fault current study to determine the available fault current at the breaker’s location and select a breaker that safely exceeds that value, balancing safety and cost.