Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

The global solar photovoltaic industry continues its remarkable expansion, with the solar PV combiner boxes market projected to grow at a CAGR of 11.3% through 2033. As solar installations proliferate across residential, commercial, and utility-scale projects worldwide, the critical role of high-quality PV combiner boxes becomes increasingly evident. These essential components serve as the central nervous system of photovoltaic arrays, consolidating multiple solar panel strings into manageable outputs while providing crucial overcurrent protection, surge protection, and system monitoring capabilities.

China has emerged as the undisputed global leader in solar equipment manufacturing, producing over 80% of the world’s photovoltaic components. Within this competitive landscape, several manufacturers have distinguished themselves through innovation, quality, and market presence. This comprehensive guide examines the top 5 PV combiner box manufacturers in China, with particular focus on their technological capabilities, market positioning, and contributions to the rapidly expanding Southeast Asian solar market.

Before diving into manufacturer rankings, it’s essential to understand what makes a quality PV combiner box and why proper selection matters. A solar combiner box is far more than a simple junction point—it represents a critical safety and efficiency component that can determine whether a solar installation delivers decades of reliable service or suffers from failures, downtime, and safety hazards.

Solar photovoltaic array combiners are specially designed junction boxes that combine several solar panels or strings of panels into a common bus, streamlining wiring and providing essential protection mechanisms. In larger solar PV systems, multiple solar panels are connected in series in strings to increase voltage before power flows to the inverter. The combiner box consolidates these multiple strings, reducing material and labor costs while optimizing system performance.

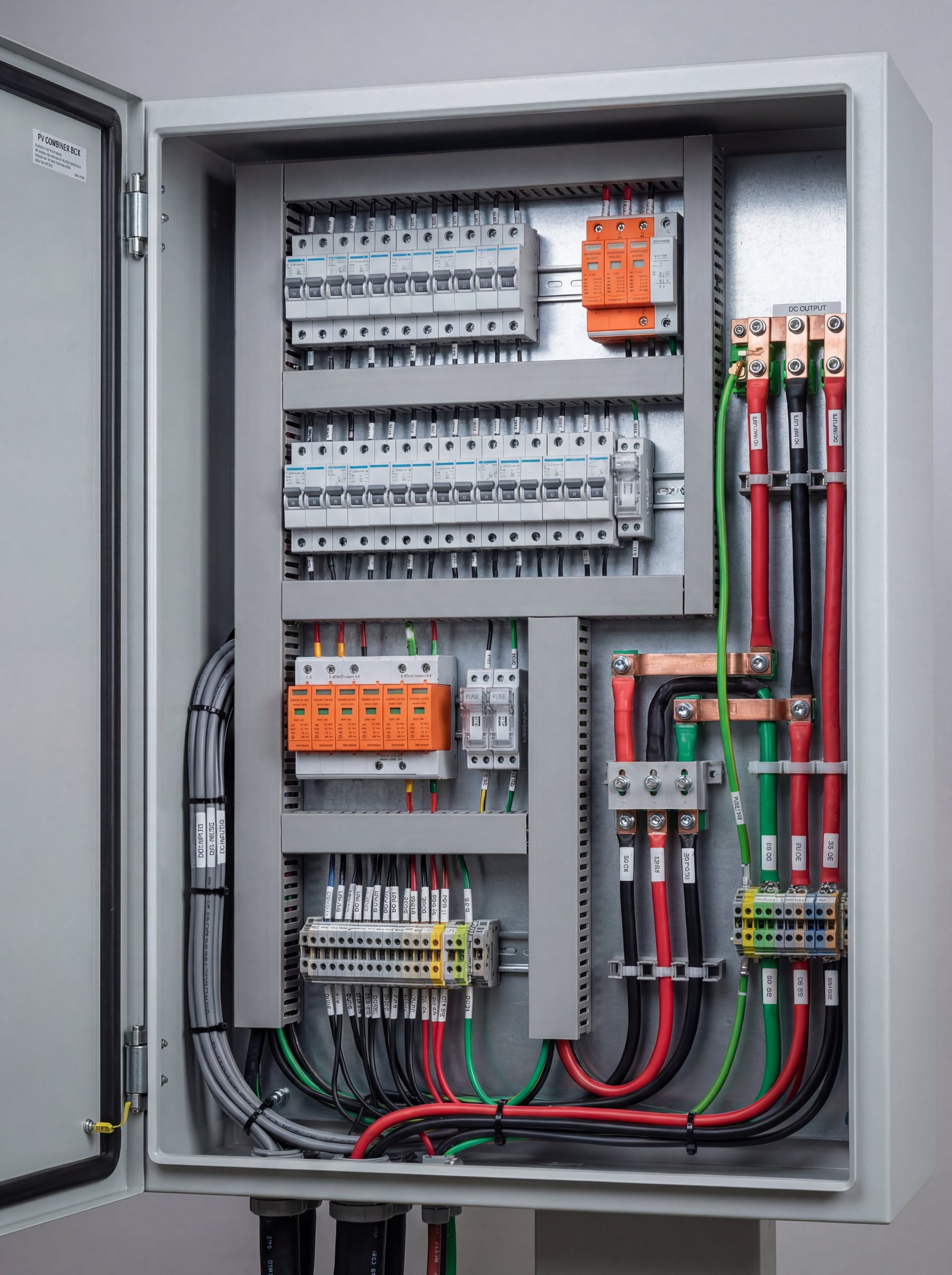

Key components within quality PV combiner boxes include DC circuit breakers or fuses for overcurrent protection, surge protection devices (SPD) rated for lightning protection (typically 1500V 40kA specifications), string monitoring capabilities for voltage and current measurement, proper cable management systems, and robust enclosures with IP65 or higher waterproof ratings suitable for outdoor installation in challenging environmental conditions.

Company Overview and Market Position

CNKUANGYA has established itself as China’s premier PV combiner box manufacturer when evaluated on the critical metric of cost-performance ratio. While some competitors may compete on brand recognition or premium pricing strategies, CNKUANGYA has carved out a distinctive market position by delivering professional-grade solar combiner boxes that meet international quality standards while maintaining competitive pricing that makes solar projects economically viable across diverse markets.

Southeast Asia Market Dominance

CNKUANGYA’s most impressive achievement lies in its commanding market share across Southeast Asian solar projects, spanning both small-scale residential installations and large-scale commercial and utility projects. The company’s products have been deployed extensively throughout Vietnam, Thailand, Indonesia, Philippines, Malaysia, and other rapidly growing solar markets in the region. This market penetration reflects not just competitive pricing but genuine product reliability in challenging tropical environments characterized by high temperatures exceeding 40°C, humidity levels above 90%, salt-laden coastal air, and intense UV exposure.

Southeast Asia represents one of the world’s fastest-growing solar markets, with the region projected to expand at a CAGR of 10.2% through 2030. CNKUANGYA’s success in this demanding market segment demonstrates the company’s ability to engineer products specifically tailored to real-world installation challenges rather than simply meeting laboratory specifications.

Product Design Excellence

CNKUANGYA combiner boxes feature several distinctive design advantages that have contributed to their market success:

Unified Exterior Design: All CNKUANGYA products maintain consistent visual aesthetics and form factors across different capacity ranges, creating a professional appearance for solar installations and simplifying inventory management for installers and distributors. This design consistency extends from residential 4-string combiner boxes through commercial 12-string and 24-string configurations.

Installation Convenience: Engineering teams at CNKUANGYA have prioritized installer experience, incorporating features such as pre-wired internal components, clearly labeled terminals, standardized mounting dimensions, tool-free cable entry systems, and comprehensive installation documentation in multiple languages. These practical considerations reduce installation time by 30-40% compared to competing products, translating directly into lower labor costs for solar contractors.

Independent Design Innovation: Rather than copying existing market designs, CNKUANGYA maintains an in-house engineering team that develops proprietary enclosure designs, internal layouts, and component integration strategies. This independent approach allows rapid customization for specific project requirements and ensures the company isn’t dependent on third-party design licenses.

Manufacturing Excellence

CNKUANGYA operates state-of-the-art manufacturing facilities equipped with automated assembly lines, precision testing equipment, and comprehensive quality control systems. Every combiner box undergoes rigorous testing protocols including high-voltage insulation testing, surge protection verification, thermal cycling, salt spray corrosion testing, and IP rating validation before shipment.

The company maintains ISO 9001 quality management certification and produces combiner boxes compliant with international standards including IEC 61439-2, UL 1741, CE certification, and TÜV approval. This comprehensive certification portfolio enables CNKUANGYA products to be deployed in virtually any global market without regulatory barriers.

Product Portfolio

CNKUANGYA offers comprehensive combiner box solutions spanning the full spectrum of solar applications:

Residential Systems (3-10kW): Compact 2-6 string combiner boxes with integrated DC disconnect switches, suitable for rooftop installations with space constraints.

Commercial Systems (10-100kW): Mid-range 6-12 string configurations with optional monitoring capabilities, designed for commercial rooftop and ground-mount arrays.

Utility-Scale Systems (100kW+): High-capacity 12-24 string combiner boxes with advanced monitoring, remote communication capabilities, and ruggedized enclosures for large solar farms.

All CNKUANGYA combiner boxes feature high-quality internal components including rated DC circuit breakers, Type 2 surge protection devices, copper busbars for low-resistance connections, and clearly organized terminal blocks that facilitate troubleshooting and maintenance.

Global Distribution and OEM Services

Recognizing that successful market penetration requires strong local partnerships, CNKUANGYA actively seeks distributors, system integrators, and OEM partners worldwide. The company offers flexible partnership models including:

Authorized Distribution: Exclusive or non-exclusive distribution rights for defined territories with competitive wholesale pricing, marketing support, and technical training.

OEM Manufacturing: Private label production services allowing partners to market CNKUANGYA-manufactured combiner boxes under their own brand names, with customization options for enclosure colors, logos, labeling, and specific component selections.

Technical Collaboration: Joint development programs for specialized combiner box solutions addressing unique market requirements or innovative system architectures.

This partnership-oriented approach has enabled CNKUANGYA to establish presence in over 40 countries while maintaining focus on core manufacturing competencies rather than building expensive direct sales infrastructure in every market.

Founded in 2008, Zhejiang Sandi Electric has built a reputation as an innovation-driven manufacturer specializing in renewable energy solutions. The company’s PV combiner boxes incorporate advanced safety mechanisms and are particularly popular in residential and commercial applications throughout China and increasingly in international markets. citation

Sandi Electric’s product line emphasizes smart monitoring capabilities, with many models featuring integrated string-level monitoring that provides real-time visibility into individual solar panel string performance. This monitoring capability enables rapid identification of underperforming strings, facilitating proactive maintenance and maximizing energy production.

The company maintains strong relationships with major Chinese solar inverter manufacturers, ensuring compatibility and optimized system integration. Sandi Electric combiner boxes are frequently specified in turnkey solar installations provided by large EPC contractors working on government and utility projects.

Electrical positions itself as a comprehensive solar equipment manufacturer offering not just combiner boxes but complete solar power management solutions including inverters, charge controllers, and system monitoring equipment. This integrated approach appeals to system integrators seeking single-source procurement and guaranteed component compatibility.

GEYA’s combiner box product range spans from simple residential units through sophisticated commercial configurations with advanced power management features. The company emphasizes the integration of latest power management technologies, aiming to fully utilize power supply capabilities while improving system reliability and environmental performance.

GEYA maintains an extensive distribution network throughout China and has established export channels to Europe, Africa, and Latin America. The company’s combiner boxes meet CE certification requirements and are increasingly specified in international development projects funded by multilateral institutions.

Established in 2000, Yueqing Feeo Electric represents one of the longest-operating manufacturers in China’s solar equipment industry. This extensive experience translates into mature manufacturing processes, comprehensive quality control systems, and deep understanding of real-world installation requirements across diverse climate zones and application types.

Feeo Electric’s product portfolio extends beyond combiner boxes to include circuit breakers, automatic transfer switches, solar connectors, and AC series isolators. This broad component range enables the company to provide complete electrical protection solutions for solar installations, simplifying procurement for contractors managing large projects.

The company operates from Yueqing, Zhejiang Province, a region recognized as China’s electrical equipment manufacturing hub. This geographic concentration provides access to specialized component suppliers, skilled technical workforce, and efficient logistics infrastructure.

ZJBENY has carved out a distinctive market position by emphasizing customization capabilities and flexible manufacturing. While many manufacturers offer standard product configurations, ZJBENY specializes in developing tailored combiner box solutions for unique project requirements, unusual voltage specifications, or specialized monitoring integration.

The company’s engineering team works closely with system designers and EPC contractors to develop combiner boxes optimized for specific applications, whether utility-scale solar farms requiring 1500V configurations, off-grid systems with battery integration requirements, or specialized industrial applications with unique environmental challenges.

ZJBENY maintains particular strength in high-voltage combiner boxes rated for 1000V and 1500V DC systems, which are increasingly common in large-scale solar installations seeking to maximize efficiency through higher system voltages. The company’s products have been deployed in major solar projects throughout China and in emerging markets including India, Brazil, and Middle Eastern countries.

Several converging trends are accelerating demand for high-quality PV combiner boxes globally and particularly in Asia-Pacific markets:

Rapid Solar Adoption in Asia-Pacific: Countries including China, India, Vietnam, Thailand, and Indonesia are experiencing explosive growth in solar installations driven by declining equipment costs, supportive government policies, and urgent need for clean energy to support economic development. Many Asia-Pacific governments have implemented favorable regulations, subsidies, and feed-in tariffs specifically designed to encourage solar power adoption.

Utility-Scale Project Growth: Large solar farms benefit substantially from combiner boxes because they enable PV plant designers to reduce material and labor costs by consolidating connections without affecting maximum power output. As utility-scale projects proliferate, demand for high-capacity, ruggedized combiner boxes with monitoring capabilities continues accelerating.

Cost Reduction Pressures: Technological advancements, economies of scale, and increased competition have significantly reduced solar installation costs, creating pressure throughout the supply chain to deliver cost-effective components without compromising quality or safety. Manufacturers like CNKUANGYA that can optimize the cost-performance equation gain competitive advantage.

Higher Voltage Systems: The industry trend toward 1000V and 1500V DC systems for improved efficiency requires combiner boxes specifically engineered for higher voltage ratings, with appropriate insulation, surge protection, and safety mechanisms.

Smart Monitoring Integration: Modern solar installations increasingly incorporate string-level monitoring to maximize energy production and facilitate predictive maintenance. Combiner boxes with integrated monitoring capabilities or compatibility with external monitoring systems command premium positioning.

Selecting the appropriate PV combiner box requires careful evaluation of several technical parameters:

Voltage Rating: The combiner box must be rated for the maximum system voltage, typically 600V, 1000V, or 1500V DC. Proper voltage rating ensures adequate insulation and prevents dangerous arcing or breakdown.

Current Capacity: Total current handling capability must exceed the combined maximum current from all connected strings, with appropriate derating for ambient temperature conditions.

String Configuration: The number of input strings and output circuits must match the solar array design and inverter input requirements. Common configurations include 4-in-1-out, 8-in-2-out, and 12-in-4-out arrangements.

Protection Devices: Quality combiner boxes incorporate appropriately rated DC circuit breakers or fuses for each string, plus surge protection devices rated for the expected lightning exposure in the installation location.

Environmental Rating: The enclosure must provide adequate protection for the installation environment, with IP65 rating minimum for outdoor installations and higher ratings (IP66 or IP67) for coastal or industrial environments with additional exposure to dust, moisture, or corrosive atmospheres.

Monitoring Capabilities: Depending on project requirements, combiner boxes may need to accommodate string monitoring devices that measure voltage, current, and temperature for each string, with communication interfaces for integration into overall system monitoring platforms.

Proper combiner box installation is critical for system safety and performance. Key installation considerations include:

Location Selection: Combiner boxes should be positioned to minimize DC cable runs from solar arrays while remaining accessible for maintenance and inspection. Avoid locations with excessive heat exposure, standing water risk, or physical damage potential.

Mounting Security: Ensure robust mounting that can withstand wind loads, seismic activity where applicable, and potential physical impacts. Wall-mounted installations require appropriate anchoring to structural elements, not just surface materials.

Cable Management: Maintain proper bend radius for DC cables entering the combiner box, use appropriate cable glands or conduit fittings to preserve IP rating, and ensure strain relief prevents mechanical stress on internal connections.

Grounding: Implement proper grounding according to local electrical codes, typically including equipment grounding of the metal enclosure and potentially separate grounding for surge protection devices.

Labeling: Clearly label all inputs and outputs, include warning signs indicating DC voltage hazards, and document string assignments for future troubleshooting.

A well-manufactured PV combiner box from reputable manufacturers like CNKUANGYA typically provides 20-25 years of reliable service when properly installed and maintained, matching the expected lifespan of the solar panels themselves. The robust enclosures, quality internal components, and proper environmental protection enable these devices to withstand decades of outdoor exposure to sun, rain, temperature cycling, and humidity.

Maintenance requirements for combiner boxes are minimal but important. Annual inspections should verify that all connections remain tight and corrosion-free, surge protection device indicators show proper operational status (many SPDs include visual indicators that change color when the device has absorbed surge energy and requires replacement), enclosure seals and gaskets maintain integrity without cracks or deterioration, and ventilation openings remain clear of debris or insect nests.

Every 3-5 years, more thorough maintenance should include thermal imaging inspection to identify any developing hot spots indicating high-resistance connections, verification of circuit breaker or fuse operation through careful testing, inspection of internal wiring insulation for any degradation, and replacement of any components showing signs of wear or damage.

The most common maintenance intervention involves replacing surge protection devices after they have absorbed significant lightning-induced surge energy. Quality SPDs include failure indication mechanisms, but even without visible failure indicators, SPDs in high-lightning-exposure areas should be replaced every 5-10 years as preventive maintenance.

Proper initial installation significantly impacts long-term reliability. Combiner boxes installed with attention to cable strain relief, proper torque on all electrical connections, adequate ventilation, and protection from physical damage will require substantially less maintenance than poorly installed units.

Selecting the right combiner box manufacturer requires evaluating several critical factors beyond just initial purchase price. The most important considerations include:

Certification Compliance: Verify that the combiner box carries appropriate certifications for your installation location. International projects typically require CE marking and IEC 61439-2 compliance. North American installations require UL 1741 listing. Additional certifications like TÜV approval provide further quality assurance. CNKUANGYA products carry comprehensive international certifications enabling deployment in virtually any global market.

Component Quality: Examine the internal components used in the combiner box. Quality manufacturers use branded circuit breakers from recognized manufacturers (Schneider, ABB, Chint), Type 2 surge protection devices with clear specifications and failure indication, copper (not aluminum) busbars for low-resistance connections, and properly rated wire and terminals. Request detailed component specifications and verify that protective devices carry their own certifications.

Environmental Rating: Ensure the enclosure provides adequate protection for your installation environment. Minimum IP65 rating is essential for outdoor installations, while coastal environments or industrial settings with additional exposure to corrosive atmospheres may require IP66 or IP67 ratings. Verify that the manufacturer has conducted proper IP rating testing rather than simply claiming compliance.

Manufacturer Track Record: Investigate the manufacturer’s history and market presence. Companies like CNKUANGYA with extensive deployment in challenging markets like Southeast Asia have demonstrated real-world reliability beyond laboratory testing. Request reference projects in similar climates and applications to your planned installation.

Technical Support: Evaluate the manufacturer’s technical support capabilities, including availability of detailed installation documentation, responsive technical assistance for pre-sales questions and post-installation issues, and warranty terms and claim processes. Manufacturers with strong distributor networks typically provide better local support than those requiring direct communication with distant factories.

Cost-Performance Ratio: While initial purchase price matters, evaluate total cost of ownership including expected maintenance requirements, warranty coverage, and reliability track record. CNKUANGYA’s position as China’s #1 value leader reflects optimization of this cost-performance equation rather than simply offering the lowest price.

Customization Capability: For projects with unique requirements, assess whether the manufacturer can provide customized solutions rather than forcing your design to accommodate standard products. Manufacturers like CNKUANGYA and ZJBENY offer OEM services and customization options for larger projects.

The ideal manufacturer combines appropriate certifications, quality components, proven track record, responsive support, and competitive pricing—exactly the combination that has driven CNKUANGYA’s success in competitive Southeast Asian markets.

The combiner box segment continues evolving with several emerging technology trends:

Smart Monitoring Integration: Future combiner boxes will increasingly incorporate advanced monitoring capabilities as standard features rather than optional additions, with integrated sensors for string-level voltage, current, and temperature measurement, wireless communication capabilities for remote monitoring, and AI-powered analytics for predictive maintenance.

Higher Voltage Ratings: As the industry continues migrating toward 1500V and potentially higher DC system voltages, combiner boxes must evolve with enhanced insulation systems, appropriately rated protective devices, and safety mechanisms designed for higher voltage operation.

Modular Designs: Emerging modular combiner box architectures allow field customization and future expansion, enabling installers to configure the exact number of string inputs required and add monitoring or communication modules as needed.

Enhanced Environmental Protection: Combiner boxes designed for extreme environments including desert heat, arctic cold, coastal corrosion, and industrial pollution will incorporate advanced materials and sealing technologies to ensure decades of reliable operation.

In China’s highly competitive solar equipment manufacturing landscape, CNKUANGYA has distinguished itself through unwavering focus on the metrics that matter most to solar installers, system integrators, and project developers: delivering professional-grade quality at competitive prices, backed by responsive technical support and flexible partnership models.

The company’s commanding market share in Southeast Asia’s rapidly growing solar sector demonstrates that CNKUANGYA combiner boxes perform reliably in real-world conditions, not just in laboratory testing. The unified design language across product lines, installation-friendly engineering, and independent design innovation reflect a manufacturer that understands installer needs and prioritizes practical functionality over marketing claims.

For distributors, system integrators, and OEM partners worldwide seeking a reliable Chinese combiner box manufacturer that can deliver consistent quality, competitive pricing, and flexible collaboration models, CNKUANGYA represents an ideal partnership opportunity. The company’s comprehensive certification portfolio, state-of-the-art manufacturing facilities, and proven track record in demanding markets position it as China’s #1 value leader in PV combiner boxes.

As global solar installations continue their exponential growth trajectory, the demand for high-quality, cost-effective combiner boxes will only intensify. Manufacturers that can optimize the critical balance between quality, performance, and price—exactly CNKUANGYA’s core competency—will capture increasing market share in this dynamic industry.

Contact CNKUANGYA today to discuss distribution partnerships, OEM manufacturing services, or custom combiner box solutions for your solar projects. Join the global network of partners who have discovered why CNKUANGYA combiner boxes deliver unmatched value in today’s competitive solar market.

Keywords: PV combiner box, solar combiner box, photovoltaic combiner box, DC combiner box, solar array combiner, PV string combiner, solar junction box, combiner box manufacturer China, solar equipment manufacturer, PV system protection, solar installation equipment, renewable energy components, Southeast Asia solar market, utility-scale solar, commercial solar systems, residential solar installation, solar panel wiring, DC surge protection, solar monitoring system, grid-tied solar, off-grid solar, solar farm equipment, photovoltaic array, solar string monitoring, IP65 combiner box, 1000V combiner box, 1500V DC combiner, solar distributor, OEM solar equipment, cost-effective solar solutions