Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

The night the Millers lost their home started with a smell. It was faint and vaguely plastic, easily dismissed as an old house settling. A week later, it was a subtle, intermittent buzzing sound from behind the living room wall, a noise so quiet it was masked by the television. They never imagined these were the final warnings of a hidden danger growing within their walls. The fire started at 3 a.m. It wasn’t a sudden explosion, but a quiet, insidious creep. A wire, decades old and nicked during a long-forgotten renovation, had finally created a persistent, high-temperature electrical arc. This tiny, continuous spark, glowing at over 6,000°C, slowly carbonized the wooden stud it was touching, eventually igniting a flame that would spread with devastating speed.

The smoke alarms blared, and the family escaped with their lives, but not their home. In the aftermath, the fire marshal delivered the heartbreaking verdict: the cause was an “arc fault.” The circuit breaker in their panel, designed to protect against overloads and short circuits, never tripped. The current drawn by the arc was too small, a mere flicker on its radar. The Miller’s tragedy is a story that repeats itself in thousands of homes every year. It’s a story about a hidden electrical hazard that traditional safety devices are blind to. And it’s a story that is, today, entirely preventable. The solution is a modern, intelligent device designed to detect that very first spark: the Arc Fault Detection Device (AFDD).

So, what is an AFDD? An Arc Fault Detection Device (AFDD) is an advanced circuit protection device that detects dangerous electrical arcs and automatically disconnects the power before a fire can start. Think of it as a smoke detector for your electrical wiring. While a traditional circuit breaker only monitors the quantity of electricity flowing through a circuit, an AFDD monitors the quality of that flow.

Its primary purpose is to identify and react to the unique electrical “fingerprint” of a hazardous arc fault—a threat that Miniature Circuit Breakers (MCBs) and even Residual Current Devices (RCDs) are not designed to handle. Arc faults are a leading cause of electrical fires, responsible for thousands of residential fires, injuries, and deaths annually . They arise from common, often invisible issues:

These situations create a low-current but extremely high-temperature spark that can easily ignite adjacent materials like wood, insulation, or textiles. Because the current is often below the 16A or 20A rating of a standard breaker, the fault can persist for hours, days, or even weeks, silently setting the stage for a fire. The AFDD is the only device specifically engineered to see this silent threat and act.

An Arc Fault Detection Device (AFDD) combines traditional circuit protection with intelligent arc detection to provide a comprehensive safety solution against electrical fires.

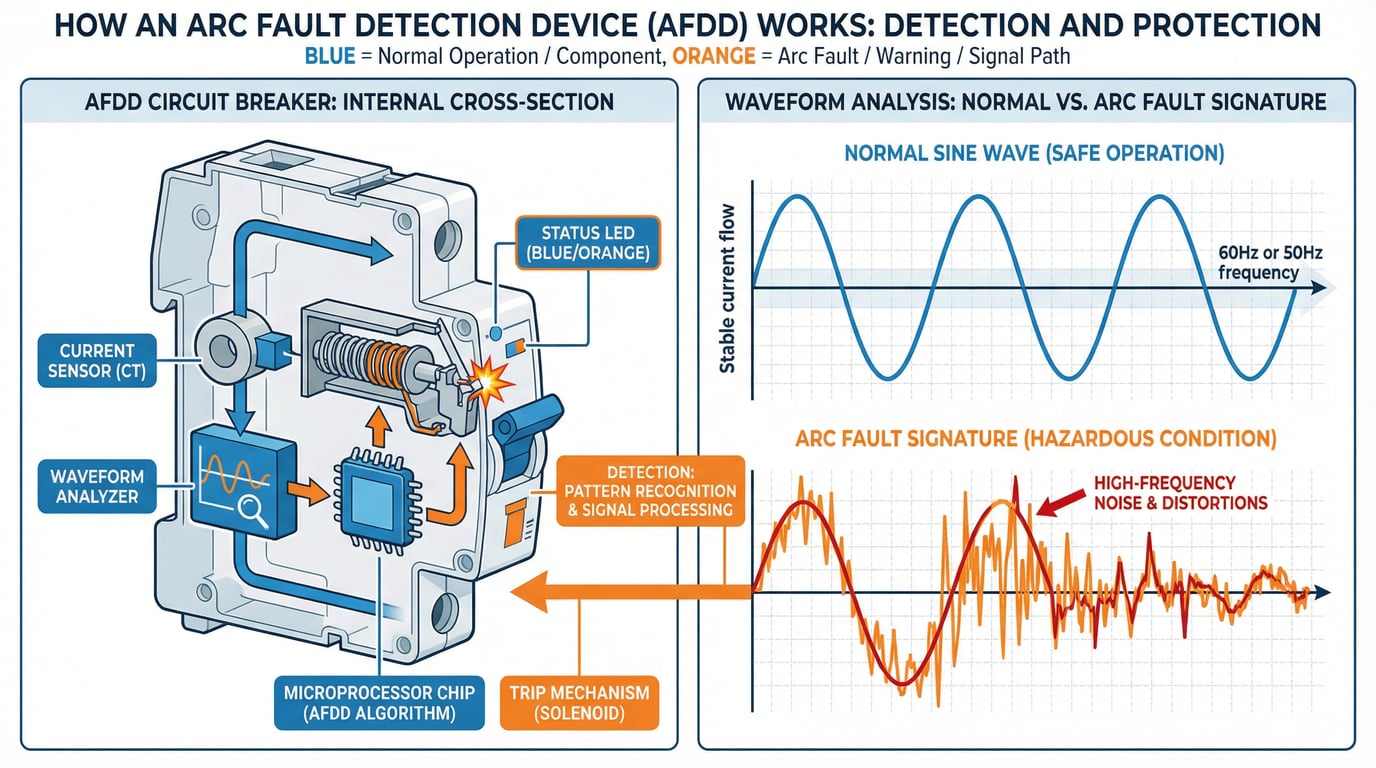

The genius of an AFDD lies in its ability to differentiate between the normal, harmless arcs that occur in everyday device operation and the dangerous, fire-starting arcs. To understand how an Arc Fault Detector works, you have to look beyond simple amperage and into the very shape of the electricity itself.

At the heart of every AFDD is a sophisticated microprocessor running a complex algorithm. This microprocessor acts as a vigilant analyst, continuously monitoring the AC sine wave—the smooth, rhythmic heartbeat of a healthy electrical circuit. It samples this waveform thousands of times per second, looking for the tell-tale signs of a hazardous arc.

A dangerous arc doesn’t behave like normal electricity. It’s erratic, chaotic, and creates a unique form of electrical noise. The AFDD’s algorithm is trained to recognize this “arc signature,” which is characterized by:

There are two main types of hazardous arcs the AFDD is designed to detect:

The AFDD’s microprocessor analyzes the AC waveform, distinguishing the clean signal of normal operation from the erratic, high-frequency “noise” created by a dangerous arc fault.

When the AFDD’s microprocessor confirms that the detected anomalies match the signature of a dangerous arc, it instantly sends a signal to its tripping mechanism, de-energizing the entire circuit in a fraction of a second—fast enough to prevent the arc’s intense heat from causing ignition.

The modern consumer unit (fuse box) can seem like an alphabet soup of protective devices: MCB, RCD, RCBO, and now AFDD. Understanding their distinct roles is crucial to appreciating the unique safety gap that AFDDs fill. Each device protects against a different type of electrical hazard.

This is a common point of confusion. Functionally, AFDDs and AFCIs (Arc-Fault Circuit Interrupters) are the same technology. The difference lies in the standards they are built to and the regions where the terms are used:

So, when comparing AFDD vs AFCI, you are essentially comparing the IEC version against the North American version of the same life-saving technology. Both are designed to detect and interrupt hazardous electrical arcs to prevent fires. Modern AFDDs often come as a single unit that also includes MCB and RCD functionality, providing all-in-one protection.

| Device | Protects Against | Primary Technology | Key Application |

|---|---|---|---|

| MCB | Overloads & Short Circuits | Thermal/Magnetic Trip | Basic equipment and cable protection from high-current faults. |

| RCD | Electric Shock (Earth Faults) | Current Imbalance Detection | Personnel safety, especially in wet areas like kitchens and bathrooms. |

| AFCI | Arc Faults (Fire Prevention) | Microprocessor Signature Analysis | North American standard (NEC/UL) for preventing electrical fires in dwellings. |

| AFDD | Arc Faults (+ often overcurrent/shock) | Microprocessor Signature Analysis | IEC standard for preventing electrical fires; often integrated with MCB/RCD. |

This table makes it clear: relying solely on MCBs and RCDs leaves a critical gap in your electrical safety. Only an AFDD or AFCI can detect the specific threat of low-current arcing that is a primary cause of electrical fires.

The adoption of arc fault protection has been one of the most significant advancements in electrical safety in the past two decades. Regulatory bodies and standards committees worldwide have recognized the technology’s effectiveness, leading to a steady increase in AFDD requirements in electrical codes. However, the specific rules vary by region.

Initially, arc fault protection was recommended only for the highest-risk areas, such as sleeping quarters where a fire at night is most dangerous. As the technology matured and its life-saving potential was proven, the scope of these requirements expanded.

The global standard, IEC 60364 (“Electrical installations for buildings”), provides recommendations for member countries to adopt into their national codes. Part 4-42 of the standard deals with protection against fire. It strongly recommends the installation of AFDDs on final circuits supplying socket-outlets in locations with specific risks, such as:

In the UK, the IET Wiring Regulations (BS 7671) have progressively strengthened their stance on AFDDs. The 18th Edition introduced AFDDs as a recommendation, and subsequent amendments have made them mandatory in certain high-risk residential buildings. As of the latest amendments, AFDDs are required in:

For all other premises, an AFDD is still highly recommended, especially for circuits in rooms where people sleep. The trend is clearly moving toward wider mandatory adoption.

The United States has been a leader in mandating arc fault protection. The National Electrical Code (NEC) first required Arc-Fault Circuit Interrupters (AFCIs) in 1999 for bedroom circuits. Since then, the requirement has expanded dramatically with each code cycle.

The 2017 NEC and subsequent versions require that for dwelling units, virtually all 120-volt, single-phase, 15- and 20-ampere branch circuits supplying outlets or devices must have AFCI protection. This includes circuits in:

The NEC’s near-universal mandate for AFCIs in new construction and major renovations underscores the consensus in the US electrical industry: this technology is not a luxury, it is a fundamental component of modern home safety.

As with any life-saving device, the quality and reliability of an AFDD are paramount. A device that fails to trip when needed, or one that trips unnecessarily (known as nuisance tripping), undermines the very safety it’s meant to provide. When selecting an AFDD, it’s essential to look beyond the price tag and consider the manufacturer’s commitment to quality, testing, and certification.

First and foremost, ensure the device is certified by a recognized, independent testing laboratory and complies with the relevant standards for your region. For Europe and the UK, this means the AFDD must be compliant with IEC 62606. Look for certification marks like VDE or KEMA-KEUR, which signify that the product has undergone rigorous third-party testing for performance and safety.

This commitment to quality is why leading manufacturers invest heavily in research and development to ensure their detection algorithms are both sensitive to genuine threats and immune to the electrical noise from modern electronics. They perform extensive testing with a vast array of appliances—from old, brush-motor vacuum cleaners to the latest LED dimmers and switch-mode power supplies—to minimize the risk of nuisance tripping. For example, companies like cnkuangya have established themselves as leaders in the circuit breaker space, offering robust 5-10 year warranties on their products as a testament to their quality and durability. Such a warranty is a strong indicator of the manufacturer’s confidence in their product’s long-term performance and reliability.

When selecting an AFDD, consider:

Investing in a quality AFDD from a reputable manufacturer is an investment in peace of mind.

A: Absolutely not. The installation of an AFDD involves working inside a consumer unit (fuse box) with live or potentially live components. This is dangerous work that should only ever be performed by a qualified and licensed electrician. An electrician will ensure the device is correctly installed, wired to the right circuit, torqued to the manufacturer’s specifications, and tested to confirm it is functioning correctly. Improper installation can not only damage the device but also create a serious shock or fire hazard, defeating the entire purpose of the installation.

A: While some early models of arc fault detectors were sensitive and could be tripped by the normal operation of certain appliances, modern AFDDs are significantly more advanced. Manufacturers have invested millions in developing sophisticated algorithms that can accurately distinguish between harmless arcs and dangerous ones. Today, if an AFDD trips, it is highly likely that it has detected a genuine, albeit potentially hidden, problem in the circuit wiring or in an appliance connected to it. Instead of seeing it as a nuisance, a trip should be viewed as an early warning that requires investigation by an electrician.

A: While an AFDD costs more than a standard circuit breaker, its value is immense when measured against the alternative. The cost of a single AFDD is a tiny fraction of the cost of the damage a single electrical fire can cause, not to mention the potential for injury or loss of life. Considering that over a third of home fires are caused by electrical faults, an AFDD is one of the most cost-effective investments you can make in your property’s and your family’s safety 2. Many insurance companies also recognize their value and may offer reduced premiums for properties with full AFDD protection.

A: Yes. This is a critical point. RCDs and AFDDs protect against completely different dangers. An RCD protects you from electric shock by detecting current leaking to the ground. An AFDD protects your property from fire by detecting hazardous arcs within the circuit. A dangerous series arc in an appliance cord, for example, will not leak any current to the ground and will therefore be completely invisible to an RCD. For comprehensive safety from both shock and fire, a modern electrical installation needs both types of protection.

The electrical systems in our homes are more complex and heavily burdened than ever before. Traditional circuit breakers, while essential, are from an era before the proliferation of sensitive electronics and the unique fire risks they can introduce. They are a vital part of a safety system, but they are no longer sufficient on their own.

The Arc Fault Detection Device represents the next logical evolution in electrical safety. It is a smart, proactive technology that addresses the single largest cause of electrical fires: the hidden arc fault. It stands guard over your circuits, listening for the faint whisper of danger that other devices cannot hear.

By detecting the spark before it becomes a flame, an AFDD provides an unparalleled level of protection. It transforms your electrical system from a passive network into an active safety system that can prevent a tragedy before it begins.

Don’t wait for a spark in the night. Consult a qualified electrician today to discuss upgrading your home to full-circuit safety with Arc Fault Detection Devices. It is an investment in property, in safety, and in the irreplaceable peace of mind that comes from knowing your home is protected by the most advanced technology available.

Disclaimer: The information provided in this article is for educational purposes only. All electrical work, including the installation and servicing of Arc Fault Detection Devices, must be performed by a qualified and licensed electrician in accordance with all local codes and regulations. Always consult a professional for advice and work related to your electrical system.